-40%

CUSTOM FLAT-TOP VALVE & PISTON for Crosman 1377, 1322, 1300KT, 2289G, PC77

$ 60.72

- Description

- Size Guide

Description

This listing complies with eBay's air gun guidelines found here and I will only sell and ship air guns to buyers in jurisdictions where permitted by applicable laws - http://pages.ebay.com/help/policies/firearms-weapons-knives.htmlTHE PISTON BASE HAS RECENTLY BEEN RE-SHAPED TO ALLOW THE LOCKING COLLAR TO BE TIGHTENED MORE THAN EARLIER VERSIONS, CUSTOMERS WERE OVER-TIGHTENING THEM CAUSING THE BASE TO MUSHROOM AND BIND IN THE TUBE, THE NEW SHAPE ELIMINATES THAT ISSUE.

EXTENSIVE RESEARCH, TESTING AND DEVELOPMENT WENT INTO ENGINEERING THESE PARTS. EVERY DETAIL OF THEIR DESIGN AND THE MATERIALS USED IS TO PRODUCE THE BEST POSSIBLE BALANCE OF PERFORMANCE AND DURABILITY. THERE'S A LOT OF INFO ON HOW TO INSTALL, ADJUST, LUBRICATE AND OPERATE THEM FURTHER DOWN THIS PAGE. IT'S CRITICAL TO UNDERSTAND ALL OF THAT TO GET THE BEST PERFORMANCE

The valve is not a modified Crosman valve, it's re-designed for maximum power and consistency and machined from 7075-T6 aluminum bar stock.

This is the new Magnum Airpower

®

custom flat-top valve and piston kit.

The

valve

body has a larger ID with shorter threads, the cap is larger ID with shorter threads and a deeper chamber, the valve-stem seat being further forward adds volume and allows the pin on the valve-stem to stick out a little further to open wider. It has more air volume than any other 13XX valve on the market but due to the pin on the stem sticking out a little further and the short angled port it empties faster and more completely with less hammer force. It's the same outer dimensions as a factory valve.

The custom piston pin is machined from tool steel with radiused ends to match the internal tube contour, this reduces scoring inside the tube. The piston base is machined from Delrin for ultra-smooth pumping and to function as a compression buffer to help protect metal parts from excessive stress. The piston rides on the Delrin base and o-rings with no metal-to-metal contact to reduce scoring and wear.

It produces more power at up to 10 or 11 pumps but falls behind the cup-seal version in the 12-17 pump range. It produces extremely tight shot to shot consistency generally within 2-3 FPS which is as good as it gets for any airgun type and works exceptionally well for precision shooting. To maintain the best possible performance, occasional piston adjustment and piston seal replacement is required, the piston seals will need replacement more often if used in dusty or dirty environments.

C

hrony results for this piston kit are similar to the ones in our listing for the cup-seal version, we will have chrony results for this flat-top version posted soon.

We also have a cup-seal version listed that is better suited for dirty/dusty environments and long-term use without having to adjust the piston or change the piston seals as often. Cup seals generally last a decade or longer even with daily use and the piston, if adjusted correctly, generally doesn't need to be adjusted again for years if ever. It produces slightly more overall power in the 12-17 pump range but slightly less power than the flat-top version at lower pump counts. It's almost as consistent as the flat-top version, generally within 5 FPS from shot to shot.

READ ALL OF THESE INSTRUCTIONS, THERE ARE DIFFERENCES WITH THESE PARTS YOU NEED TO BE AWARE OF

Once the piston is adjusted to length, snug the locking collar down with a pair of pliers while holding the base with a 3/16" pin punch or similar tool. Thick strips of folded paper, cardboard or leather can be wrapped around the locking collar to keep it from being marked by the pliers. It is not necessary to torque the collar extremely tight, just snug it down moderately for the best overall function. If the piston is adjusted too long it won't allow air to enter the tube when the pump lever is in the open position, if the gun won't pump up then this may be the cause. The valve stem sticks further out then the original factory valve, it's often necessary for the hammer to be in the cocked position for the valve to hold pressure.

The valve exhaust port is radically angled to produce more power. Because it's angled the opening looks oval rather than round. This is not by mistake, it's supposed to be this way. The transfer port gasket fits and seals effectively with the .150" ID of the port, do not enlarge the port ID, it will not seal with the gasket correctly if you do. Further enlargement of the valve port will not gain more power, matching your transfer port and barrel port to the same .150" diameter will at higher numbers of pumps.

12 Pumps or less is recommended for regular shooting, 13-17 will produce more power but causes the pivot-pin holes in the tube and pump lever to wear faster. They elongate over time and more force applied to them at high numbers of pumps speeds that process up. They can last for many years, even decades, if lubricated regularly and not over-stressed persistently.

The Delrin piston base helps reduce wear by compressing slightly under high pressure, this acts as a buffer reducing stress on the metal parts.

INSTALLATION :

You will need a wooden dowel to install the valve without damaging it or the tube. 1/2" Diameter by 12" or longer works well, hardwood is better but softwood will work also.

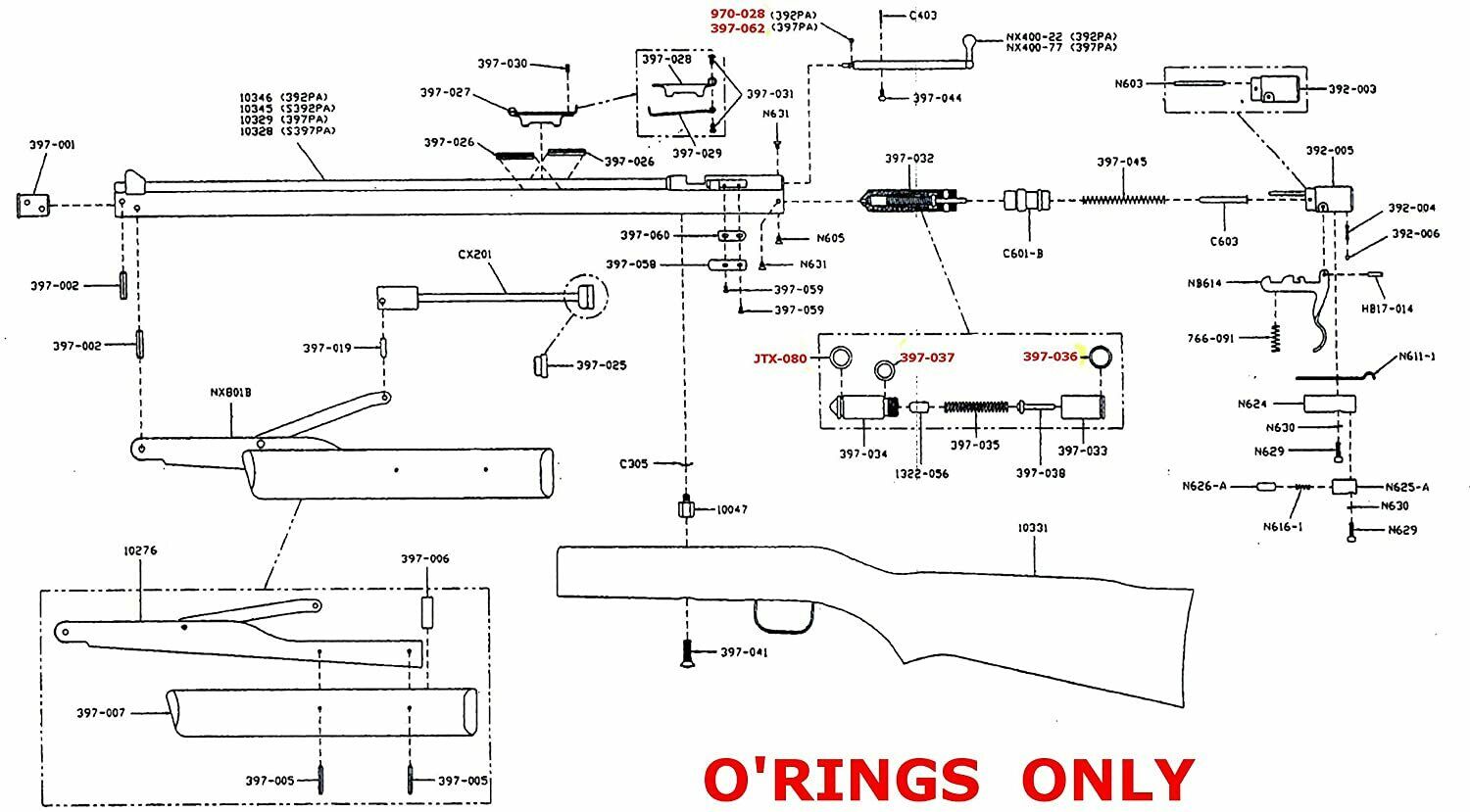

The valve seals internally with an o-ring. The two halves should not be twisted tight together, there should be a slight gap between them. This allows the position of the port to be adjusted to either side after installation. Most 13XX tubes have those holes slightly out of alignment. Being able to adjust the port by twisting it to one side or the other is necessary for correct alignment. Once the valve is in position, put the trigger frame in place and install the front frame screw lightly, this holds the valve cap in place while you adjust the port. Use a pin punch, hobby paintbrush handle or similar object to gently turn the port until it's centered in the tube hole. Placing the gasket on top of the valve helps to check if it's centered. Once centered, push the valve in tight with the wooden dowel to make sure it's seated snugly against the stop in the tube, then remove the dowel and tighten the frame screw firmly.

The piston needs to be adjusted correctly to work well and avoid damaging the gun. The forearm should close with moderate resistance, not need to be forced. The piston should compress against the valve face with moderate clamping force to hold the forearm up snugly. Holding the valve stem open with the wooden dowel through the back of the tube allows you to test the piston while pumping. The air will escape through the barrel so you can feel the fit and function of the piston without pressure. If you have a stiff hammer-spring and/or power adjuster the hammer may hold the valve open when the bolt is not cocked. This helps check the piston adjustment the same way as using a wooden dowel, the gun may also need to be cocked for the valve to hold air once assembled.

The cup seal on the piston is the standard Crosman version, very easy to find if it ever needs to be replaced. It will last for many years, typically decades if oiled correctly and the gun is stored unloaded with two pumps in it. Oiling instructions are explained below.

Oil the outside of the valve, piston and seals before installing. We made these valves fit tighter than the original factory valves for performance reasons. They seal better at the o-ring and transfer-port gasket because there's less gap between the tube and valve. This reduces pressure loss during the firing cycle producing more power. The valve should be pushed into place with the wooden dowel. If your tube is bent, dented from hard pumping or has deep stamped lettering the valve may fit tight and need to be tapped in with the dowel and a hammer. If it fits excessively tight you can use a different tube or there's a simple way to fix your tube posted in the next paragraph. We tested dozens of new and used tubes to make sure they fit correctly in most cases. Only one in a dozen or so tubes will have issues. The valve is machined from solid 7075 aluminum, it's very hard and durable and won't generally be damaged from pushing firmly or tapping it in moderately hard. If it fits extremely tight it's better to start with a new tube or use the fix

mentioned below.

HOW TO FIX TUBES THAT FIT THIS VALVE TOO TIGHT :

13XX Valves sometimes fit a little too tight in the tube, this is caused by some tubes being slightly bent or not perfectly round from the factory. Also the valve tends to get stuck where the stamped lettering starts on the tube, there's dimples from that stamping on the inside, some tubes have deeper stamping than others so some are a tighter fit. This happens with about 1 out of every 10 tubes from our experience. The easiest fix is to use a small piece of sandpaper, wet/dry works best, 400-600 grit, to hone-out the high spots. If you use a 1/2" dowel or something similar like the straight section of a plastic coat-hanger, you can use a piece of duct tape to attach a 2" wide strip of the sand paper. Wrap it around the dowel and trim the length of the strip so the "sanding drum" you're creating fits comfortably snug (not tight) into the tube. Use a twisting motion to get the sandpaper in the tube without it unraveling. This will let you twist and hone the higher spots off so the valve will fit. Don't polish the inside of the tube too much, polishing will cause the piston seals to bind which makes it harder to pump and can damage the piston seal. We use a specially-made hone to do this which takes about 10 seconds. Even doing it with a dowel and sandpaper only takes a few minutes, you don't usually need to remove much material for the valve to slip in comfortably.

LUBRICATION :

Variable-pump models should be assembled with oil to lube all the seals and moving parts. Add a drop of oil directly into the pump chamber every couple hundred shots. You can do this more often if the piston isn't working smooth or produces inconsistent performance. If you accidentally over-oil you can fire the gun with the barrel pointed straight up, unloaded and safely away from you. In that position excess oil settles near the valve stem and blows out through the barrel. To prevent oil-lock, only use two pumps for each shot until excess oil is cleared from the pump chamber and valve. A drop of oil should be applied to all pivot points of the pump lever and one at the back of the piston seal. This will lubricate the contact points of the piston.

An instructional video is in the works for installing and adjusting these parts along with our other custom 13XX upgrades. In the meantime do some research and make sure you understand how to install and use them, they are intended for experienced customizers and builders.